The Pipe Renewal Revolution

Why Choose CarboSeal®?

Transform the way you approach infrastructure maintenance. CarboSeal® is replacing subterranean service pipes and structures with little or no excavation.

Fast

Simple

Sustainable

CarboSeal® References

Efficient Rehabilitation by SFAB in Stockholm: CarboSeal Liners in Action

Read more ReferencesWe made it possible

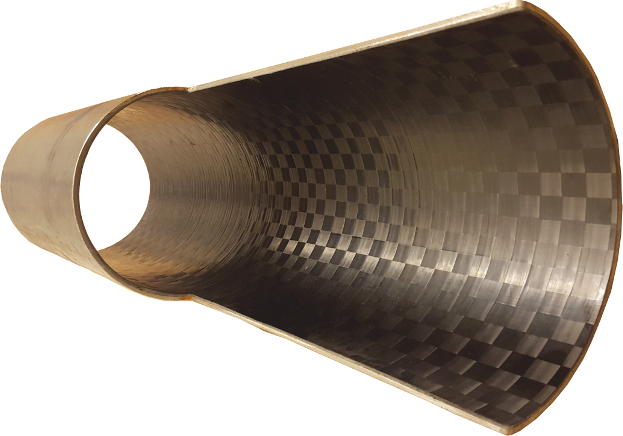

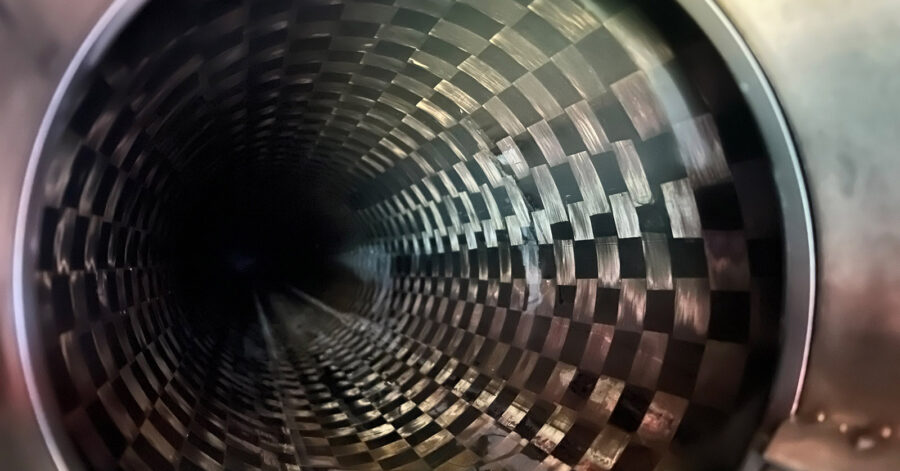

A Unique Solution

No-Dig, no Interference

Trenchless Rehabilitation Solution

Relining for District HeatingCarboSeal is a unique solution for rehabilitating district heating pipes that are structurally unsound. This non-invasive method ensures that pipe renewal will have minimal impact on the immediate surroundings, leaving other networks and structures in and on the ground unharmed.

Closing a Gap in the Market

Relining for District Heating

Until 2021, the market could not offer a liner for trenchless rehabilitation of district heating pipes. The materials traditionally used for pipe lining cannot withstand the high-heat, high-pressure corrosive environment in and around district heating pipes. CarboSeal is the solution.

New from Old

Taking over the Workload of the Host Pipe

The system is designed to completely take over the workload of the host pipe, leaving it fully renewed. Distances of up to a few hundred metres can be rehabilitated in one working day, with little or no excavation.

Stay tuned

Latest CarboSeal® News

BKP Berolina Acquires Majority Stake in CarboSeal® Manufacturer PPR Sweden

Velten, Germany / Borås, Sweden – April 2, 2025

CarboSeal® Achieves Outstanding Results in Long-Term District Heating Liner Test

PPR Deutschland GmbH, in collaboration with AGFW | Der Energieeffizienzverband für Wärme, Kälte und KWK e.V. and Stadtwerke Neumünster,...

Norrenergi uses sustainable no-dig method to renew district heating pipes in Stockholm

Norrenergi renewed a pipe section in the Stockholm district heating network without excavating or replacing the old pipes. The energy...