Norrenergi

Energy network owner Norrenergi operated a district heating network in Sundbyberg, north of Stockholm, Sweden. The network pipes were ageing and needed repair. As the system capacity exceeded the existing energy consumption, diameter reduction was implemented when installing new pipes. This reduced the pipes from DN 400 to DN 300 in most of the system.

One section running under Rissneleden, a main road to Sundbyberg, had not been replaced, as an excavation would have significantly impacted traffic. Trenchless rehabilitation using CarboSeal® was proposed, but it came with a few challenges. Because of the dimension changes and the fact that an inaccessible compensator chamber was located several metres below the roadway, a unique solutionwas required. Additionally, there wasa 12°bend in relation to the chamber exit.

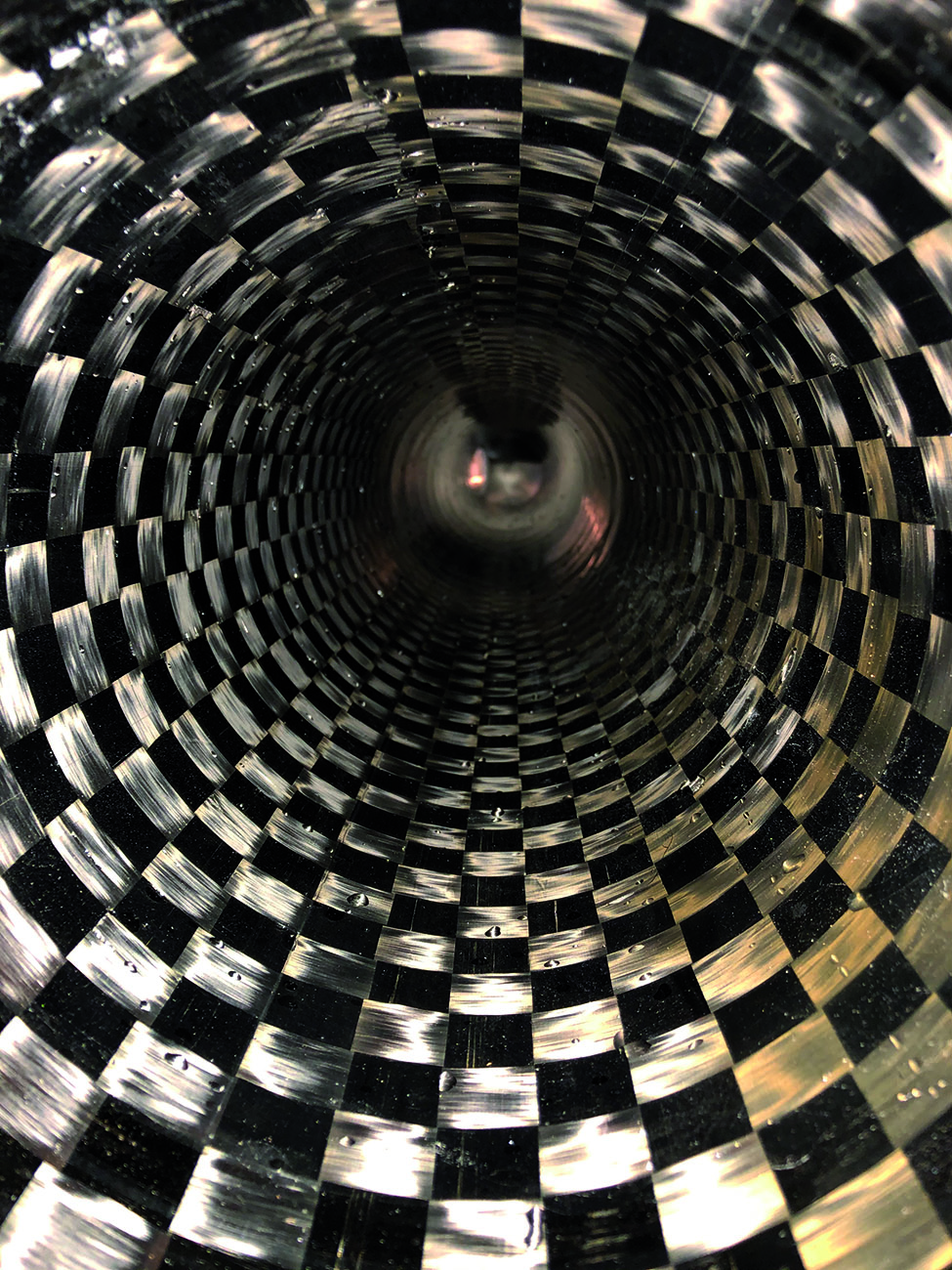

PPR came up with a solution to cure a DN 300 CarboSeal liner inside a full-length DN 300 dimensioned burst bag and proposed it to Norrenergi and project coordinator Fjärrvärmeprojekt Sverige AB. The DN 300 liner was naturally to be laying at the bottom of the old DN 400 pipe. Burst bag versions were developed and tested to verify that they would endure the installation process, and an aramid burst bag was chosen. A test rig was constructed off-site to mimic the dimension changes, the bend and the free-standing liner setup. Installation trials in the test rig verified the solution, and the actual installation was planned.